Quality

![]()

The ingot and wafer represent the base and the most important part of the module manufacturing process. Unlike other module manufacturers, we carefully produce our own ingots and wafers in-house. Using the latest silicon technology and advanced ingot seeing, only the highest performing wafers are produced and used for JinkoSolar modules. Advanced ICP-MS (inductively coupled plasma mass spectrometry) and PL photoluminescense testing ensure the utmost wafer quality.

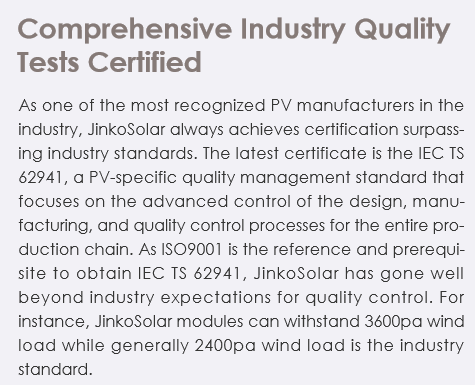

JinkoSolar has state of the art, automated solar manufacturing facilities across the globe and an unblemished quality record. We ensure that each module shipped complies with the highest quality standards.

We have taken extra steps to ensure that our modules are second to none with our rigorous in-house quality control standards. In addition to passing all standardized tests, we invite the world’s leading 3rd party institutes, including the Australian Solar Council Positive Quality Program, to audit our facilities, test our products, and help us refine our world class manufacturing process.

Guaranteed 100% Quality

The production process includes 52 tests which are performed on our modules before delivery to our customers. We perform Electroluminescence Tests on 100% of our cells prior to lamination and post lamination on 100% of our modules, assuring they have no micro-cracks.

Our traceable quality system allows us to directly cross reference our solar cells with particular production parameters. Furthermore, each solar cell contains a code allowing us to answer questions about your JinkoSolar module even more efficiently.

Partnership with Top Material Suppliers

JinkoSolar provides customers with products made with raw materials of the highest standards to meet the reliability requirements of various kinds of installations and climate conditions.

JinkoSolar has signed a strategic collaboration agreement with DuPont, one of the leading suppliers of advanced photovoltaic materials such as metallization pastes, and Tedlar backsheets, among others. This type of agreement reinforces JinkoSolar’s position of manufacturing high quality products with the best power outputs possible.

JinkoSolar Won Best Module of the Year 2020, PV Magazine’s Most Prestigious Award

JinkoSolar has won the prestigious PV Magazine Award 2020 in the module category thanks to its Tiger module series. Every year PV Magazine gathers experts and representatives from PV industry to award the best technological innovations and breakthrough solutions in the photovoltaic and energy storage fields. A total of 115 companies participated in the selection for this year’s edition, 38 industry representatives entered the finals, and 7 award-winning companies were finally selected. The jury has recognized JinkoSolar’s Tiger module for its outstanding ultra-high performance and quality, especially its innovation in TR technology, which eliminates the cell gap to increase module efficiency significantly.

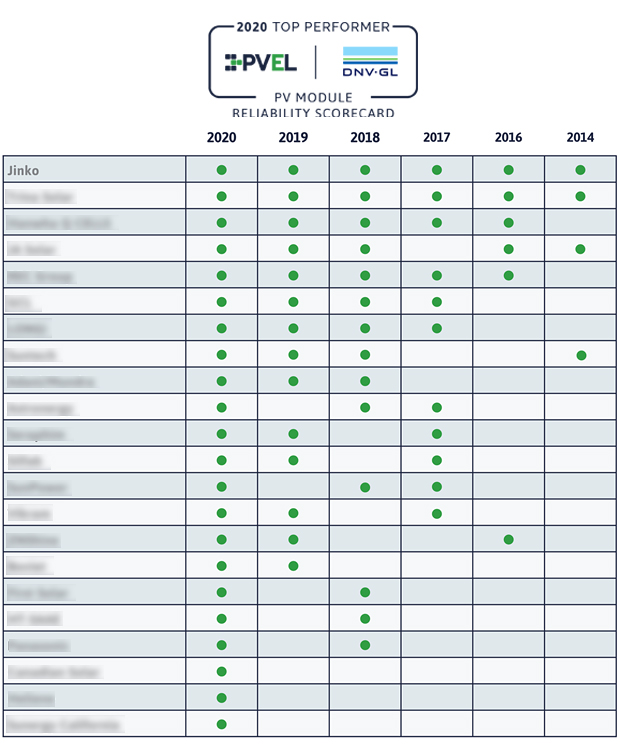

JinkoSolar Recognized as Top Performer in PVEL/DNV GL 2020 PV Module Reliability Scorecard

JinkoSolar has been ranked as a Top Performer for the sixth consecutive year in the 2020 PV Module Reliability Scorecard, published by PV Evolution Labs (“PVEL”) in partnership with DNV GL.

The PV Module Reliability Scorecard ranks PV manufacturers and modules based on their reliability and performance. The PV Module Reliability Scorecard remains the most comprehensive publicly available comparison of PV module reliability test results across the PV industry. Independent testing was carried out by PV Evolution Labs’ Product Qualification Program (PQP) which set higher benchmarks this year when compared with 2019.

Since 2015 part of the Smart Energy Council “Positive Quality Program”

A team of specialist engineering inspectors visits on a regular basis Jinko manufacturing facilities. The visit happened without notice and they carry out a full comprehensive review, conducting physical testing and checking the full manufacturing process as well as business registration, tax registration and testing certifications in details. The testings’ results confirms once again the high quality and reliability of JinkoSolar products.

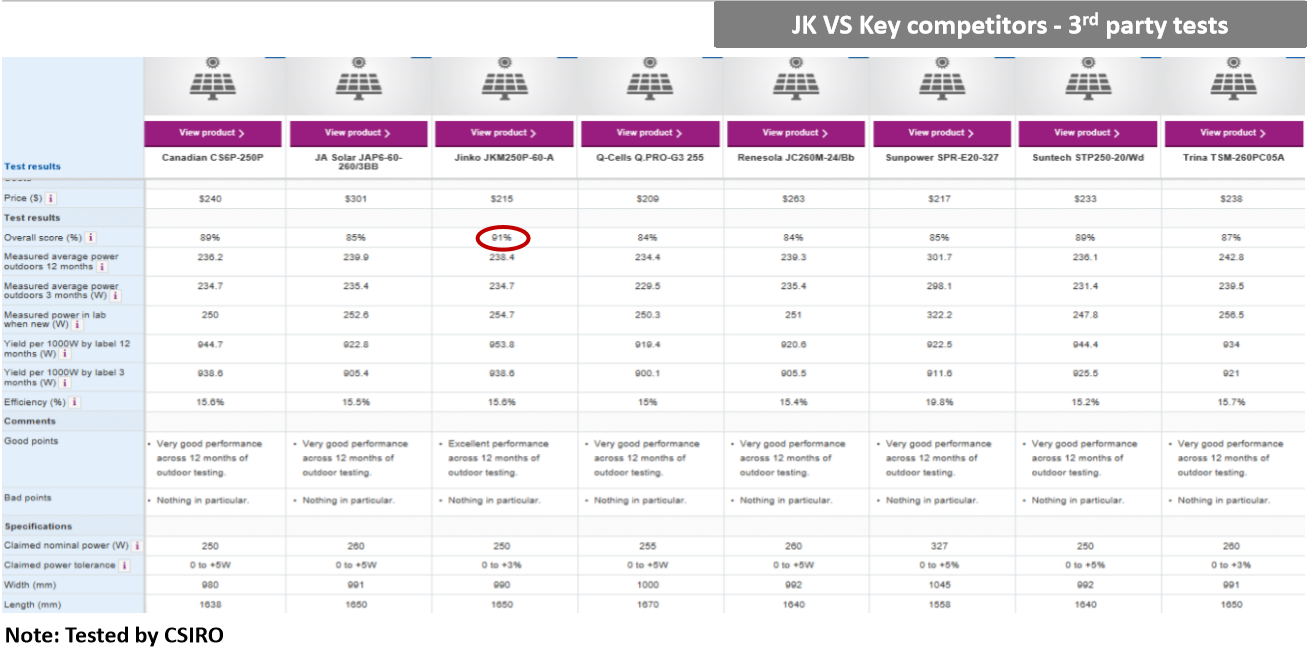

CSIRO Module Test Results

The CSIRO and Choice Magazine have partnered to test the performance of a range of solar modules commonly purchased in the Australian market. After 12 months of testing at the CSIRO testing facility in Newcastle, JinkoSolar was one of just two module manufacturers to receive a score of excellent and above 90%. Our energy yield per 1000w was significantly above all our competitors.

Jinko Solar Panels: An Independent Review by Solar Choice

Jinko Solar is a Chinese company that was founded in 2006 originally producing silicon wafers. The company now has an annual production capacity of 17.5 GW of monocrystalline silicon wafers, 10.6 GW of solar cells and 16 GW of Solar Panels as reported on their website in March 2020… [read more]